Here is a write up with pictures of what I did to the V70 phase one, slightly later engine than yours but look at the internal pictures of the sump later in the write up which shows where it can block, note any prices quoted are for the parts from the Volvo main dealer bu tthey are in UK Pounds.

This is a quick set of pictures showing how to get to the PCV on the V70/ early S80 with the Denso engine management system without a Turbo, the engine should appear thus:

Start by taking the cover off to gain acces to the coil packs as you will need to remove the top hose from the PCV system later on, at the same time remove the plastic cover from the fuel rail:

Take off the inlet pipe running between the mass airflow sensor and the electronic throttle motor, there are a couple of other pipes connected to this that need disconnecting and an electrical connector but the pipe should come away leaving the engine looking like this:

Next to come off is the Electronic Throttle Motor, four 10MM headed bolts will release it from the inlet manifold but the cable is trapped between the starter motor and the engine block so secure it somewhere safe within the engine bay, take the oppertunity to clean it out on both sides of the butterfly valve with carb cleaner while it is away from the engine

Disconnect the wiring from the injectors and put the loom out of the way, no need to number the plugs as it is obvious what goes where assuming the conduit is still in one piece:

Disconnect all the Vacuum lines from the inlet manifold:

Put some cloth or kitchen roll around the valve on the end of the fuel rail and depress the valve in the center of the schrader valve, fuel will escape but you need to depressurise the fuel system before taking the injector rail to bits, once no more fuel is escaping throw the fuel soaked rag in the bin:

Remove the two 10MM head bolts securing the fuel rail to the inlet manifold and the pull the fuel rail complete with the injectors away from the engine, take care at this point as the fuel delivery pipe is still attached to the fuel rail:

Invert the fuel rail to reveal the three Torx head screws securing the clamp plate which locks the fuel injectors and fuel delivery pipe to the fuel rail:

Remove two of three screws and release the third screw to let the clamp plate slide out to the side, try not to knock any of the injectors at this point, once the securing clamp plate is clear of the fuel delivery pipe simply pull the pipe from the fuel rail:

With the fuel rail disconnected from the delivery pipe remove it from the engine bay and put it somewhere safe, as a tip slide the clamp plate back in to place and put the two Torx head screws back in to avoid the injectors falling out, this also keeps the two screws safe from getting lost:

Next is the black plastic injector vapour purge pipe, this simply pulls away from the inlet manifold, again put it somewhere safe:

Follow the dipstick tube down to where there is a bracket attached to the underside of the inlet manifold, you need to release this, the bolt is 12MM head, once this is off the car feel further aft towards the engine under the inlet manifold to locate another 12MM head bolt between a bracket that connects between the engine and inlet manifold, remove the bolt between the bracket and the inlet manifold:

Next remove the top PCV vent hose from the top of the engine, if it has a crimp type clip attaching it to the head use a screwdriver to lever the clip to release the pipe, the clip will be scrap and is best replaced with a suitably sized Jubilee clip on reassembly:

Remove all the upper bolts securing the inlet manifold to the engine block, the three lower nuts only need to be released as the inlet manifold is notched to aid removal, with a 6" wobble extension it is possible to release the inlet manifold bolt near the thermostat even if it is difficult to see the nut!

To release the lower bolt on the right side of the inlet manifold it is easier to use a 10MM spanner as there is no access for the ratchet:

To get the inlet manifold off simply lift it up to clear the lower stubs then push the PCV top hose through the pipes and the fuel rail through the inlet feed pipes, put it to one side as you now have access to the PCV, time taken to get to this point is around 30 minutes.

Remove the bracket that connects between the inlet manifold and the engine block as one of the bolts securing the PCV tank to the block is hidden behind it:

With the bracket out of the way remove the two bolts securing the PCV tank to the front wall of the engine block, even the second bolt is fairly well hidden:

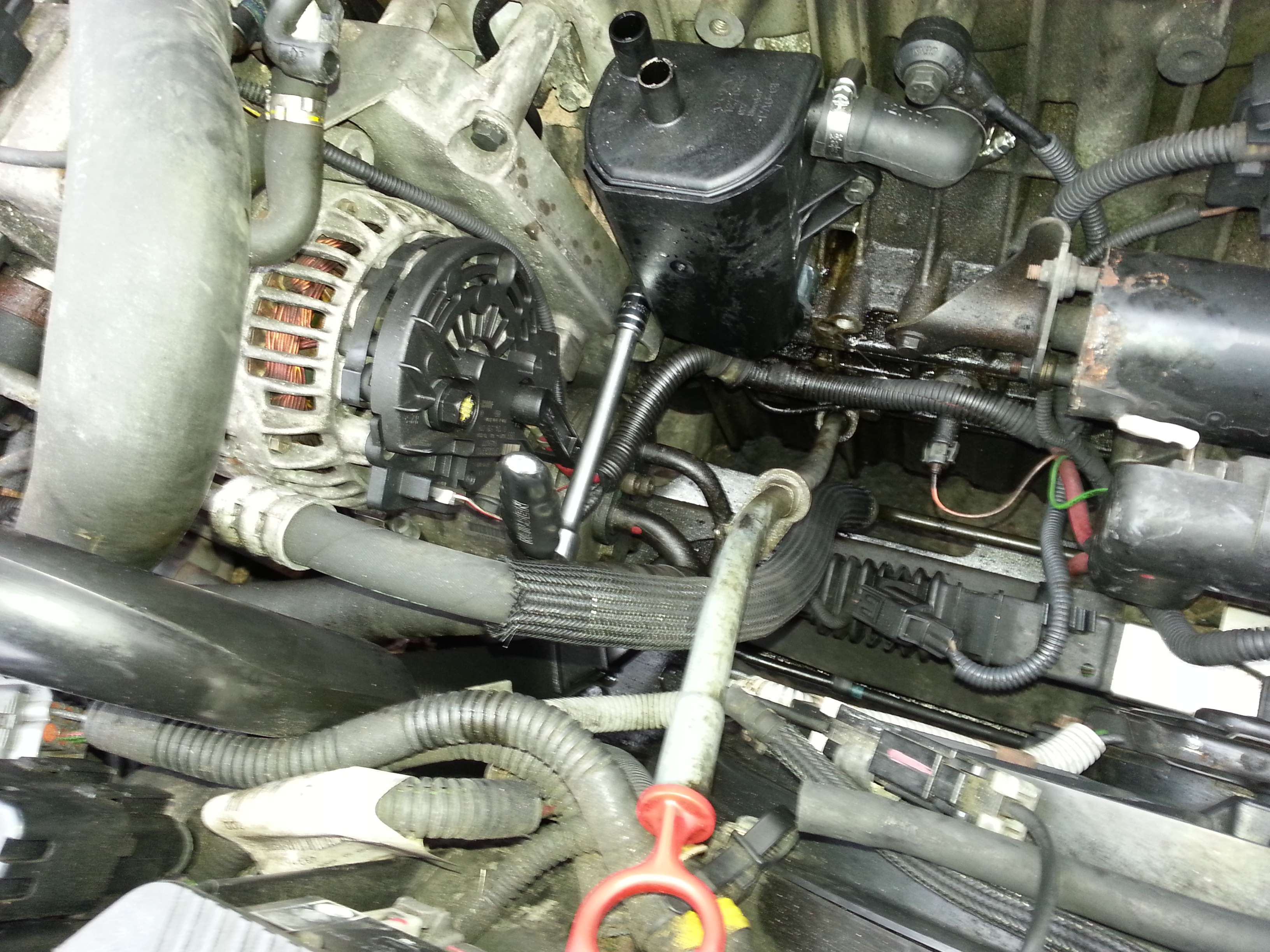

Sorry for the state of these next few pictures but I was using a phone with hands soaked in oil by now! with the PCV tank pulled away from the engine you can get at the coupling between the lower engine port and PCV tank, this is where the oil drains back to the sump from the PCV and is often the port that is most blocked/ sludged up:

The small silver coupling piece simply pulls from the engine block to reveal the port (and sludge):

At this point attach a 5/8" internal diameter hose to the lower PCV tank port in the engine and try to blow through it, if you can blow through it and hear bubbling from the sump the port isn't blocked, if you can't blow through the port it is blocked and needs to be cleared out to address the PCV issue:

I decided to send a length of clear plastic pipe down the lower PCV port to try and unblock it, the sludge and carbon built up inside the pipe which was reduced in length cutting off the now blocked section of pipe before repeating numerious times until no further sludge could be removed, not ideal and if it is this bad consider an oil change before starting the engine as some of the crud might have dropped in to the engine sump. In my case the PCV port was still blocked and I couldn't blow through the 5/8" hose (more on this later in the write up)

The blow-by pipe from the PCV tank to the inlet manifold is heated by the engines coolant system, it is possible to take this to bits without disturbing the coolant system and clean out the pipes, to do this strip off the innsulation and take the pipe off the coolant pipe:

When you are sure the PCV drain is clear refit the metal/ rubber collar to the lower port:

Refit the tank and secure the hoses with Jubilee clips rather than the crappy Volvo crimp connects, the tank costs around £30 new and the two small connections to the engine block are around £3:50 each, a new pipe to the top of the head is close to £40, the PCV blow by pipe I cleaned out and re-used, adding innsulation when rebuilding.

When you refit the bracket to the engine that supports the inlet manifold leave it loose until you have attached the inlet manifold as this makes it far easier to connect the two items, once you have the bolt secured in to the underside of the inlet manifold secure the bracket fully to the engine

After that little lot the reassembly is really the reverse of taking it to bits, the first time I tried this took me around two and half hours the second time was around an hour excluding time taken to clear out the blocked ports on the engine.

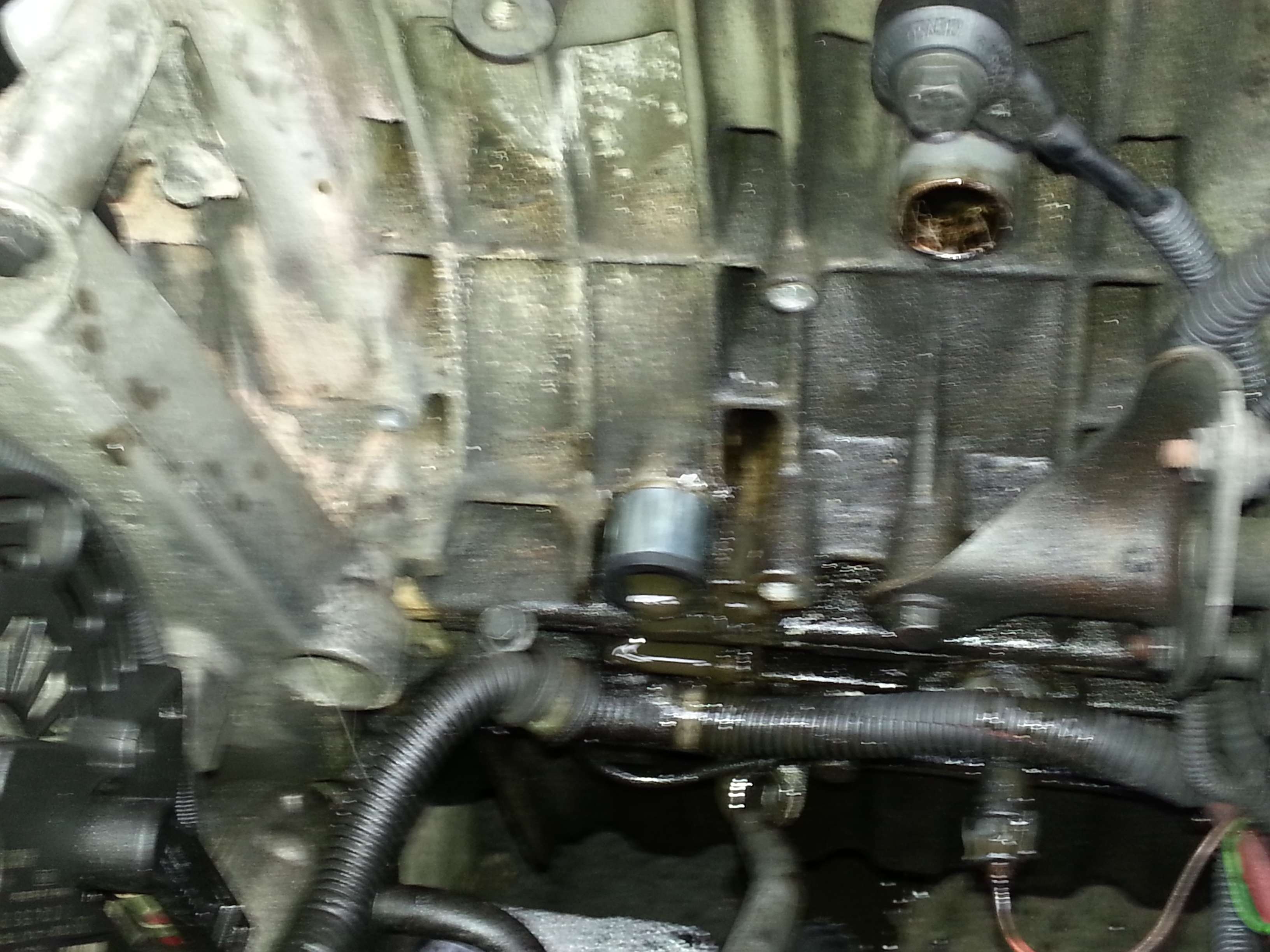

In the end the sump had to be removed to clear out the oil return path as it was blocked with carbon, you can see where the PCV drains down through the square part of the casting then exits to the sump through a pipe that is close to 180 degrees bent upwards relative to the drain port, this 2" section of port is impossible to clean out without removal of the sump which is why the blowing down the 5/8" hose earlier in the write up is so important as sump removal is a real PITA:

- Mike